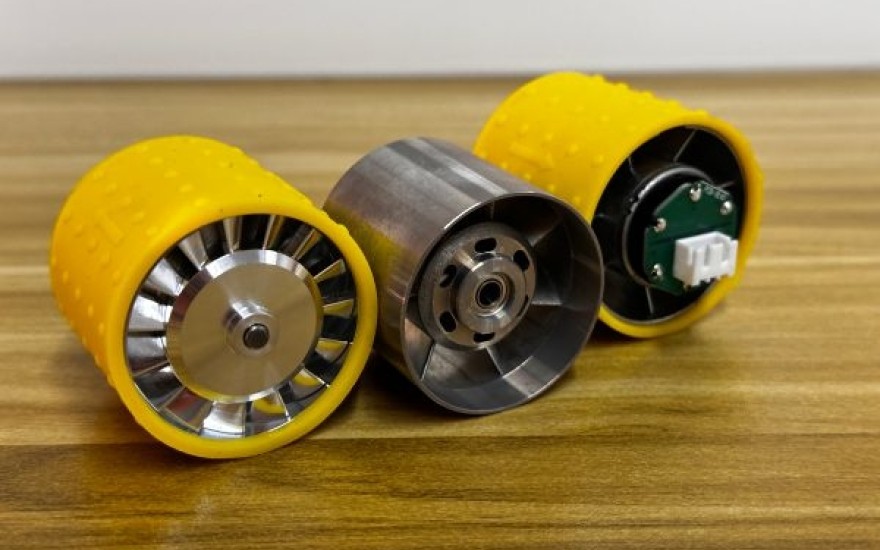

CNC turning part, 5000 pcs., US

I am thrilled to share insights from a recent project involving the production of an industrial dryer, specifically focusing on a highly stressed component that operates at over 130,000 RPM.

This project posed significant challenges, particularly in ensuring the reliability and safety of the part under such extreme conditions.

To meet these demands, we recognized the need to enhance our quality control processes. It's crucial to understand that not every component requires the same level of scrutiny; thus, we tailored our QC measures to align with the specific needs of each part. By implementing a more rigorous quality assurance framework, we successfully minimized risk while maintaining efficiency in our procurement processes.

The outcome?

Our customer is 100% satisfied with the results, reaffirming our commitment to excellence and delivering carefree procurement solutions.